A Q&A with Katun’s Vice President of Hardware and Business Solutions, Tony Ko, led by the BPO Media | Office Technology Group, President and Analyst, Patricia Ames

Patricia Ames: Congratulations on the big Arivia launch! It’s exciting and also very unusual to have a new OEM enter the market. Our readers have lots of questions, so we are thankful you found some time amongst all the flurry to talk with us. Katun is a very well-known partner in the office equipment channel, but maybe not everyone is familiar with you, Tony, so I wanted to begin by asking you how you got started at Katun. I know you have been with the company a long time.

Tony Ko: I started at Katun 29 years ago, basically as a marketing analyst, supporting multiple team members here in Minneapolis. Back then, we had not established the business unit roles that we have currently — a lot of the marketing functions are now decentralized and are being performed in their individual world regions. Everything back then was supported out of the Minneapolis office, so we had a marketing team of 20-30 people supporting all the different markets and regions of the world. I supported the US and Latin American markets for about two years, and then when we opened up the Katun Singapore office, I became the marketing manager for the Asia Pacific region. That meant a lot of travel to the area, working with our sales teams there, visiting with customers and distributors throughout China, Korea, Southeast Asia, even Australia. That allowed me to gain a lot of input from our customers in terms of what they needed and what they were struggling with. I did this throughout the late 90s.

During that time, the economic crisis within Southeast Asia occurred, so that became a huge issue for us trying to figure out how to help our partners survive. They were more worried about how they could get enough money to get food on the table for their families, rather than worrying about buying all the things that I was asking them to buy. It was at that point that I started having a real understanding of my customer, understanding what is important to a customer from a survival perspective in a very cutthroat industry. Everybody was trying to get a little piece of a shrinking pie. That was the start of that process for me, supporting that scenario from a regional perspective.

Since then, I have served in many roles at Katun and was able to gain experience in almost all areas of the business from all angles, but my earliest days at Katun helped set my guiding principles. From that point on, my focus has been on gaining a deep knowledge of our partners’ requirements and needs and defining their pain points in order to build a catalog of understanding of our partners so we can innovate.

PA: It sounds like you are the tip of the spear. What has your role been in this big A3 development project? Are you the tip of the spear?

TK: I am the head of the hammer. I have been involved with this project from the very beginning. Together with a small executive team, we visited and communicated directly with the potential partners in Japan. This was during COVID, so everything was a little bit challenging as you can imagine. At the time, Japan was basically closed to visitors, so there were quarantines and tight restrictions on movements. There was a lot of plexiglass. We were negotiating every element of our proposal, working through every detail with their teams on contract negotiations in terms of the agreement, what is or what is not going to be included, and ultimately, what we wanted in terms of a product portfolio to match the needs of our partners that we were trying to support. We’ve had over 40 years of experience supporting partners and the data that entails, so we had a very clear idea of what was required. The bulk of the products that our partners have been buying from us are products that feed into their 25 to 65 ppm machines. That dictated how we wanted to build our new equipment portfolio.

PA: Why A3s instead of A4s? The trend seems to be going in the opposite direction.

TK: I would say there are two elements to that. First of all, Katun has a much longer history with A3 products. Our support for the partners is far more heavily weighted toward A3 products. And the other element comes from the Katun aftermarket consumables and parts and supplies perspective.

Partners have been asking us for years to make our own A3 product. They understand the depth of our expertise in this category. So it has been in the back of our mind to do something specifically in this space. When our ownership changed and growth became more of a focus, the timing seemed right.

PA: What about A4 – any plans for that?

TK: A4 is a developing storyline.

PA: What has been the most challenging aspect of this launch?

TK: Probably the most challenging aspect for me personally is simply my involvement with every element. As the tip of the spear and the head of the hammer, I have to be involving a lot of individuals within and outside the organization, and making sure everybody is incorporated on all relevant elements right from the very beginning. Systems had to be integrated, partners have different ways of doing things, different technical perspectives, assumptions and understanding can be different, communication is not always clear — this was an incredibly complex project. I’ve been having very long days and very long nights, but I’m just so energized by the opportunity!

PA: Well – you are in start-up mode.

TK: You’re truly accurate in that! When this project began, I had to ask my team to work on certain things but couldn’t tell them why. It started first with “doing,” and then building an organization around that.

PA: What are you most excited about right now?

TK: What I’m most excited about right now is seeing how the results of our efforts benefit our partners.

PA: What are the advantages to the dealers of this new line you’ve launched?

TK: I think the product itself is not the most relevant thing anymore. A3s all have the same basic capabilities at this point. That’s not where we can differentiate. The really important thing for the partners is trust. We are trusted. They know working with us is a lot easier than working with their other OEM partners. We don’t have the same sorts of pressures, which alleviates the need to constantly drive up the volume of orders. We don’t have a factory that’s pushing us. We don’t have a manufacturing development team pushing us to sell more of what they’ve developed. Our objective is around supporting our partners and offering an alternative. How can we be the OEM that they wish they had? We want to address what is really important to the partner. How can we make business easier? How can we make transacting with Katun less troublesome than it is with their other OEM partners? How can we simplify things for them in terms of our products, our consumables, our equipment? How can we be different enough for them that we reduce whatever pain points they have going on in their dealership right now? Clicks are down, margins are being squeezed, they need growth.

PA: How then are you going to talk about product differentiation with your partners?

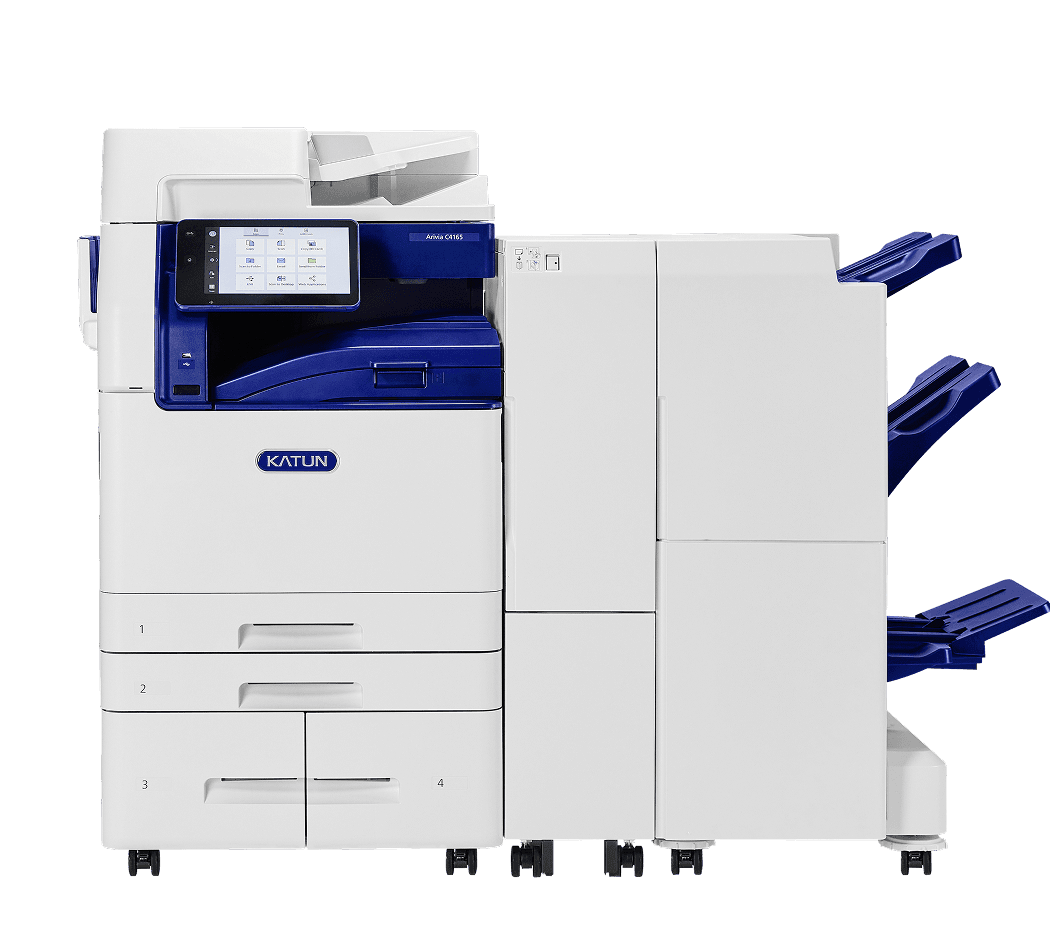

TK: The differentiation is not coming from equipment specs, it is in how we approach doing business. It’s in terms of our quest to simplify things for our partners. For example, how can we minimize the number of SKUs that a partner has to carry to support all of our devices? We are launching a fairly robust line of machines across the model and color space. Some OEMs mandate that the partner needs to carry multiple sets of different toners for the different families of equipment. We’ve been able to start from scratch and so have been able to minimize SKUs as much as possible based on the engine development aspects. We’ve picked the configuration that maximizes the capabilities without forcing a partner to buy an ever-expanding list of options. Of course we have all the normal options that a customer might want to add like sorters, staplers, hole punchers — we have all that. But if a customer just wants a basic, standalone device with high input capacities, well, it’s already configured for that.

Another example — we want to ensure that our devices are compatible with whatever MPS platform our partners have today. We’re not in the business of trying to sell them machines with a new MPS platform. Our job is just to let them know our product is tested, confirmed and compatible. On the other hand, if they don’t like the platform they currently have, our business units have been selling different MPS platforms for years and can help them make an informed decision.

Our core value is not making our partners do something different than what they’re doing today, other than replacing whatever machine that they don’t like from whatever OEM that they are not so fond of anymore with a Katun product.

Simplify Your Success

We’re here to help you succeed. Let us be your trusted ally in the ever-evolving print industry.

Get Started